Turbo Blowers and Turbo Compressors

What industrial equipment our company offers

The SmarTurbo consortium conducts research and development in the field of industrial high-speed devices. This includes the enhancement of Turbo Blowers, Turbo Compressors, and Turbo Aerators through the integration of air bearings, automatic control systems, and other components. Our consortium representatives are involved in supplying and maintaining equipment in many countries, including the USA.

About the manufacturer of SmarTurbo Turbo Blowers & Compressors

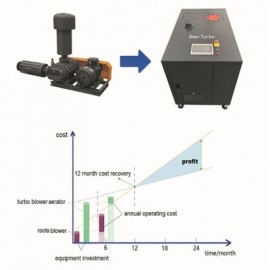

SmarTurbo represents a group of modern companies specializing in scientific research, development, manufacturing, and the supply of technologically advanced high-speed Turbo Blowers, Turbo Compressors, and Turbo Aerators. SmarTurbo's approach to innovation includes the development and implementation of a comprehensive research system focused on creating highly efficient engines with magnetic or air bearings and advanced aerodynamics. Adaptive systems for adjusting the operating modes of SmarTurbo devices ensure their optimal performance, while the ability to control Turbo Blower, Turbo Compressor or other appliance via a mobile device is convenient for users. This allows us manufacture to guarantee high equipment efficiency, by reducing electricity costs by up to 50% and simplifying maintenance.

Why Choose SmarTurbo Blowers and Compressors

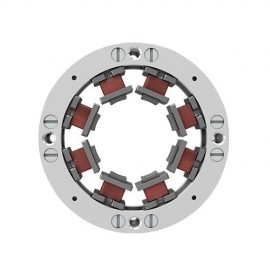

Our specialists have developed and continue to refine the design of high-speed engines with air and magnetic bearings, leveraging SmarTurbo's robust research base. The engine's advanced components and aerodynamics allow for achieving maximum energy savings and reduce maintenance costs for Turbo Blowers, Turbo Compressors, and Turbo Aerators. SmarTurbo's leading positions in the market are a testament to the quality of its main components.

-

In-house Research and Development

SmarTurbo designed a thoughtful system that combines the research and development of components for high-speed engines for chargers, compressors, aerators, and other devices.

-

Upscale Machining Center

SmarTurbo developers have access to a wide range of CNC machines, 5-axis machining centers, and other advanced equipment.

-

Standardization of Machining Processes

Machining processes are standardized for better automation. The standard and precision of the equipment provide high-quality components of turbocharger casings, impellers, bearings, and overall engine part machining.

-

Advanced Testing Equipment

State-of-the-art testing equipment for the engines and individual parts ensures the accuracy and quality of the final products, such as turbochargers, turbo compressors, and so forth.

-

Intelligent Manufacturing-Assembly Line

The assembly production line is designed according to a special project for comprehensive production efficiency and achieving better quality of turbo equipment.

-

Standardized Testing Process

All parts of Turbo Blowers, Turbo Compressors, and other equipment undergo testing to guarantee their stable operation.

Application

Turbo blowers and Turbo compressors are widely used in the fields of sewage water treatment, high-density shrimp aquaculture, cement plants, oil and gas industry, biopharmaceuticals, flue gas desulfurization in power plants, oxygen production, printing and dyeing textiles, paper-making, chemical engineering, food etc.

News & Evens

Our automatic production line have reached an annual output of 5000 sets of air bearing and support batch production and air bearing customization.